Part holding fixtures are critical for precisely holding and locating parts. Most such fixtures use locators for positioning. No matter how well a fixture is designed, unless the parts are properly positioned against the locators—every time—mistakes will occur. Automation only makes this problem worse because unlike humans, robots are, generally, unable to make fine adjustments to workpiece positioning.

Spring-loaded devices are a common solution to reliable part positioning. A key feature is that when the workpiece is positioned horizontally, spring-loaded devices play the additional role of retaining the workpiece before and after clamping. In automated systems and pallet pools, this function is critical to prevent damage to the work center. Attachments For Mini Excavator

There are a wide variety of spring-loaded devices on the market, including spring locating pins, spring stop buttons, ball plungers and spring plungers. Here are some practical tips on their features and how best to use them.

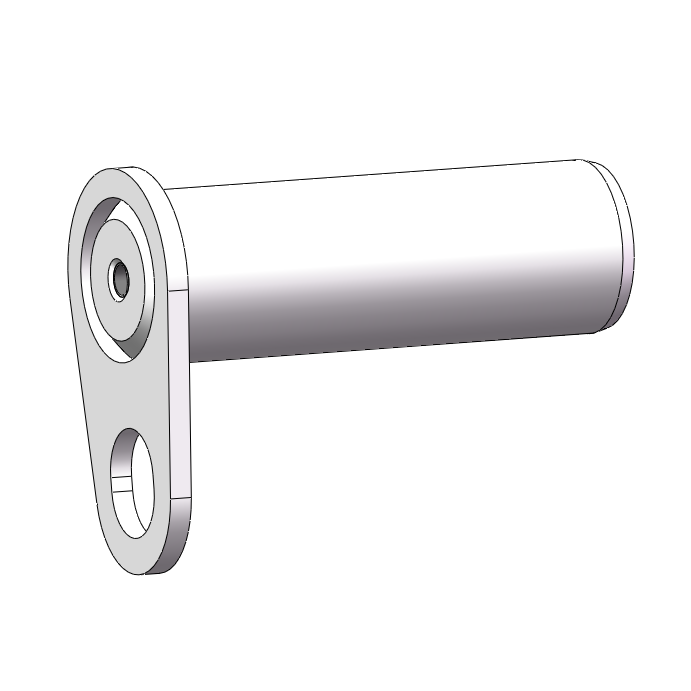

Spring locating pins push the part against fixed locators. This ensures proper contact during clamping. Spring locating pins help reduce errors by correctly positioning the part against the locators. In addition, the pins also eliminate the need for a “third hand” when clamping some parts. Their small size and compact design make them useful for smaller parts or confined spaces. A protective rubber seal around the contact pin helps seal out chips and coolant.

Spring stop buttons are another commonly used spring-loaded device. These units work much like spring pins, but they are designed for parts where more travel or force is needed. Spring stop buttons are made with three different contact faces. The first is a spherical button contact; the other two have flat contacts. The flat-face contacts are made either with or without a tang.

Spring plungers have a cylindrical plunger with a rounded end. Spring plungers are well suited for a variety of applications, such as the workpiece ejector. They can also be integrated into other fixture elements to provide force in any necessary direction.

Spring plungers are available in various lengths and end pressures, in stainless and mild steel. They are also available with Delrin plungers for applications where marring is a concern. Spring plungers have nylon-type locking elements on the threads.

Part sensing uses spring-loaded devices as the most efficient way to ensure the proper loading of workpieces, but verification should be used to prevent expensive errors. When a workpiece is not properly loaded, and automated clamps are signaled to perform, operation clamps can be easily damaged. This process interrupts production and results in downtime. There are two types of part sensors: physical contact sensors and proximity sensors.

Air-sensing rest devices allow one or more rest buttons to act as both a rest button and a sensor. A modular unit consisting of a threaded body is installed in a fixture, which holds a precision floating plunger. This plunger has a reamed or tapped hole available in a choice of three diameters and accepts any height of standard press-fit-type rest buttons.

Proper placement of a workpiece on the air rest button assembly causes the plunger to fully retract into the body. This seals off airflow, which increases the overall pressure of the system (30 psi maximum air pressure). This pressure value can be read using an analog or digital pressure sensor, which can then be tied into a PLC or control system.

The primary advantage of a physical contact sensor is that it is difficult to “fool” or “foul.” This is a common issue in the subtractive manufacturing process, which produces metal or plastic chips. These chips can build up around a sensor and send a false positive. The air sensing rest button further reduces the potential for fouling by positioning the sensor under the workpiece.

There are applications when a physical contact sensor is not possible or appropriate. They include applications with light workpieces, high-speed sensing applications, and applications with complex geometry.

Through-hole rest buttons are non-contact sensors consisting of a 0.06" (1.52-mm) through hole that allows air to travel through and detect whether a part is loaded using an air-gap measurement sensor. These sensors use back pressure, created when loading the part, to measure the distance between the end of the rest button and the workpiece. Unlike physical contact sensors, non-contact sensors can be mounted in a variety of ways. The through-hole rest button also contains a #10-32 tapped hole on the shank for installation of a threaded nipple for easy air-line installation.

Clamp position monitoring: Once it has been determined that the workpiece has been loaded properly, the workpiece can be clamped. Before machining can begin it is ideal to determine that the clamps are in the appropriate position. Typically, this position monitoring is only available on clamps powered through pneumatic, hydraulic, or electric means.

Adjustable pneumatic position monitoring uses a small pneumatic cylinder that is contacted by a bolt attached to a clamp arm to depress the cylinder, increasing pressure in the system that can then be monitored by a gauge. This system is used most often in applications where workpiece size varies slightly from part to part, such as sand castings.

Pneumatic position monitoring uses a switch rod connected to a signal sleeve inside of a housing. The signal sleeve creates back pressure within the pneumatic monitoring loop, which can be monitored using a gage. This type of device requires additional space below the fixture.

80mm Excavator Pin Electric position monitoring uses adjustable inductive proximity switches and a switch rod. Unlike pneumatic versions, they typically require no additional sensors, nor do they increase plumbing complexity. They are not typically suitable in applications that require them to be disconnected frequently. Coolant and metal chips also present hazards to electrical components. Special care is required when using electricity in machine tools.